You make products.

You create experiences.

You have product vision & want to make it reality

You know design-for-manufacturing is key

You produce

300-3000 units per year

Welcome to PROTOMET

A partner to bring your brand to life

A partner through thick and thin

See what we’re made of. We have catered our services to support product development for leading brands in the recreational industry. We are a one stop shop, leading with design and ideation, progressing towards rigorous engineering, and ending with full service manufacturing that molds to your supply chain.

Tuned to ideate & execute your product vision

Deep expertise in design-for-manufacturing

Geared to produce and ship your product,

week after week

Your One-Stop-Shop for turning ideas into prototypes and prototypes into daily production

From our Customers:

-

Supra Boats has put a lot of trust in Protomet as a partner since we started working together in 2014... Protomet’s commitment to improving people and processes as well as working alongside our product development team to innovate has been an important factor in the Supra brand’s success.

Ryan Lewis, Supra Boats

-

"The product development process is full of uncertainty. As a result, it's critical we find partners we can trust. Whether we are relying on Protomet's manufacturing & finishing expertise, engineering design support, or are working to reduce manufacturing costs, we can trust Protomet's insight, feedback, and products."

Aaron Marohl, Nautique Boat Company

-

“Protomet’s in house engineering team has extensive manufacturing knowledge and has on many occasions been able to redesign my part to be cheaper to manufacture while improving the fit and function. ”

– Design Engineer, Caymas Boats

-

“We are always presenting challenging designs and Protomet keeps providing exceptional results. They work with us from the first sketch up through production to ensure our products exceed expectations."

– Design Engineer, Manitou Boats

-

"In 'Protomet's Essence', Jeff and his team vividly capture their core values. Engaging with Jeff is a journey into the heart of learning and envisioning a brighter tomorrow. Life's trajectory is deeply influenced by the company we keep. I cherish the wisdom and camaraderie we've shared over the years.”

Thomas Bates, Correct Craft

-

"The products designed and built by Protomet are just one piece of the puzzle. Honestly my favorite thing about having Protomet as a partner is the people...you can see the belief in their culture, pride in what they do every day."

Chris Crysdale, Skiers Choice

-

Protomet pushes the limits of new products. They have an improvement mindset and will move mountains to bring a project to life. World class service dressed in blue polos may be the best way to sum it up.

Clint Howell, Tige Boats

-

“The leadership at Protomet is outstanding. They promote hard work, communication, and next level service. Even more, this mentality propagates throughout the entire company.

Chris Owen, Montara Boats

We partner with brands to add

function and beauty to their products

Industrial Design

It begins with a vision. If your starting place is a napkin sketch, we can mold that into a rendering that brings your concept to life. Our in house design team understands aesthetic balance, and is particularly trained to design with manufacturing in mind.

Mechanical Design

Our mechanical engineering team is an elite group of tinkerers and explorers who know more about bearing mechanisms than you’ll care to hear, don’t get them started. Protomet designs mechanical systems that work, period.

Design for Manufacturing

Mechanical designs are brought to the tedious world of robotic programming so that we can cut, shape, engrave, bend, paint, stretch, and mold materials into the real life form of your vision. We know manufacturing, because we do it in house, ensuring the most efficient and quality manufacturing processes are employed for the full life-cycle of your product.

We offer full-service manufacturing

Move straight from design to production runs with our domestic manufacturing capabilities.

We make in AMERICA.

Here, automation meets talent.

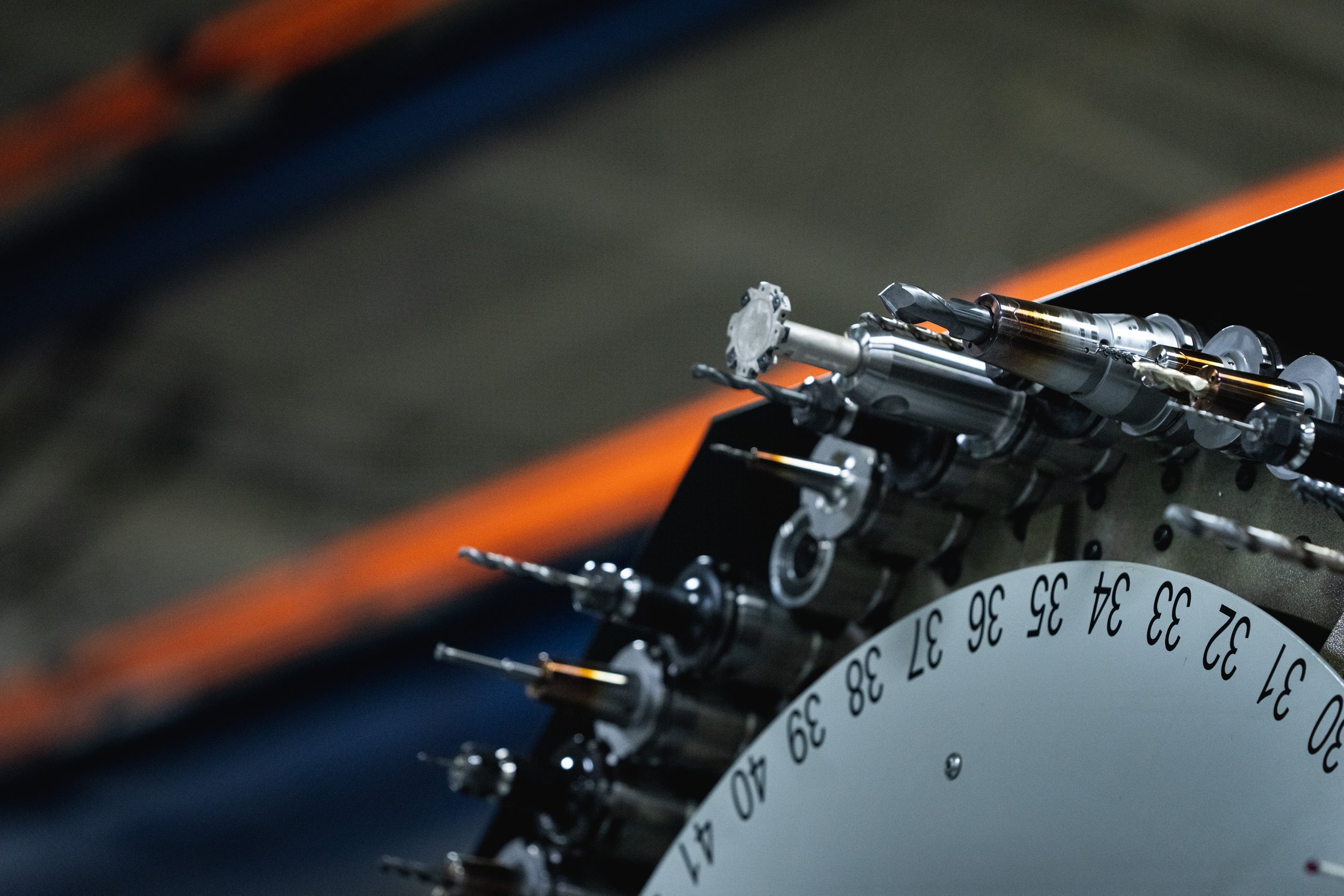

CNC Machining

CNC machining is the backbone of our manufacturing operation. We can cut materials into complex geometries with incredible precision and repeatability. Plus, since we aren’t using casts or molds, we can easily edit designs throughout the product lifecycle with the change of a few lines of code.

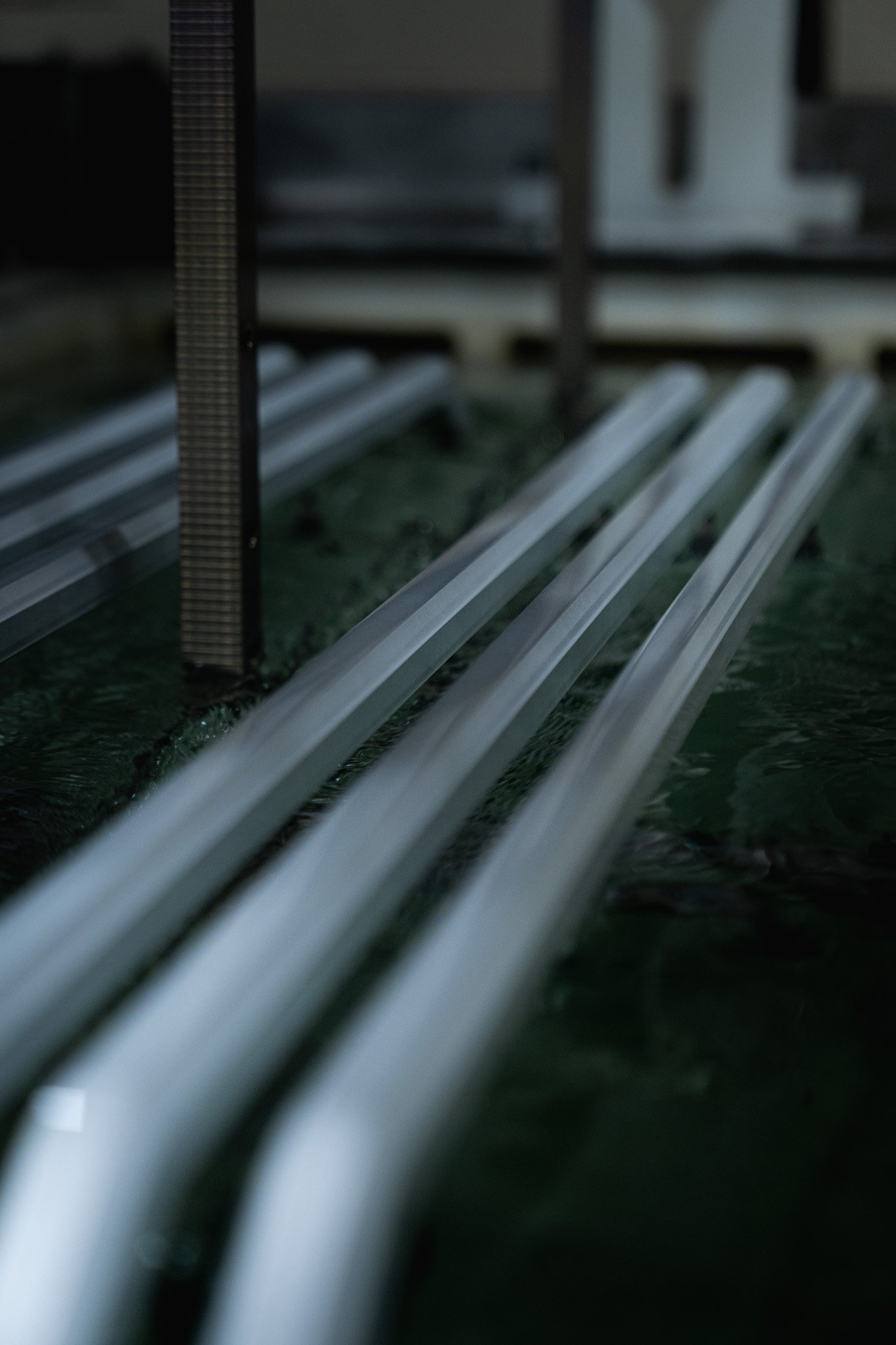

CNC Bending

Our tube and sheet metal bending is backed with laser accuracy. All bends are laser measured and computationally iterated before production runs take place. This is fabrication 2.0. We flip historically unrepeatable methods on their head.

Repeatable Welding

The best welder cannot overcome substandard weld fixturing. Luckily, we have both - the best welders in the game and engineers that have been developing weld fixture design principles for years. This combination produces an ergonomic environment that yields beautiful, strong, consistent welds and dimensionality.

World Class Anodizing

Anodizing is a miracle-finish. Practically invisible to the human eye, but strong enough to resist years of corrosion and wear. Here’s the scary part - because its microscopic, it’s easy to cheat, skimp, or go halfway. Like our whole operation, our anodizing is performed in-house with rigorous quality standards, ensuring that what you’re getting is the real deal, every time. Take it to the next level with our proprietary ShoreKote™ finish and metal finishing services. Durable enough for extreme saltwater conditions, ShoreKote™ combines the best of anodic films, conversion coatings, and polymer films into a robust finish for decades of use.

Customizable

Powder Coating

Powder coat is the fastest growing metal finish in the world due to it’s unbelievable corrosion resistance and durability. If you want custom color schemes or demand product lifecycles in harsh environments, you can have your cake and eat it too with powder coat.

Electrical Integration

Complex projects often require wire harnesses to convey power to switches, actuated assemblies, lighting systems, and other electrically dependent features. We have a state of the art electrical engineering team to ensure your harnesses are designed, built, and quality tested with 21st century tech.

Full Service Assembly

Protomet’s assembly team is crafted for mid-volume jobs, where we can ensure fit, function, and aesthetics are perfect for seamless installation or end-user experience. We field test all necessary components and work directly with downstream constituents to ensure needs are met and maintained.

Protomet is big on TEAM

These folks control the robots

CNC is a big word at Protomet, but these are the real drivers. Our crew ranges from expert technicians to seasoned artisans in their craft. We hustle, and don’t pay much attention to limits.

Engineer’s playground

Engineering is the heart of Protomet. If we were a tree, engineering would be the trunk that drives growth opportunities to the branches. Our engineers are curious, eager to take on new challenges, and thoroughly enjoy the iterative journey of development.

Get to know us

“We’re not looking for easy” has become a tag-line around the shop. Check out this video to get a feel for what we’re about. We’re not for everybody, but when you know, you know.

Work with us

Contact us.

You’re on a journey to develop the greatest product experiences in your industry. We’d like to support your cause. Send us a line and we’ll see how your dreams can become tangible.

support@protomet.com

(865) 425-0600

HQ: 2400 Maremont Parkway

Loudon, TN 37774